In the packaging industry, corrugated paper is a widely used material for a variety of applications. It can be used to create a variety of box designs, liners, fillers, cup holders and more. Corrugated paper is widely used in packaging in industries such as food, electronics, household items, toys, etc. due to its high strength, light weight, and customizability.

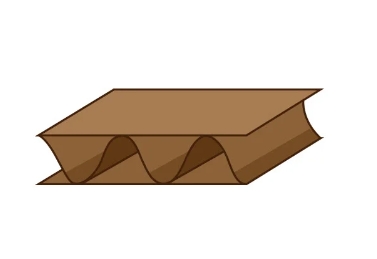

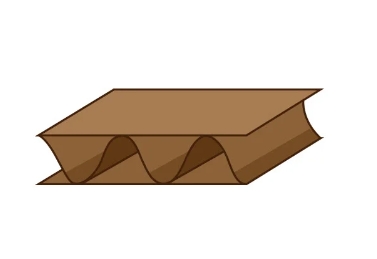

Corrugated cardboard material

Corrugated fibreboard, corrugated cardboard or corrugated paper is a packaging material consisting of corrugated cardboard and one or two sheets of flat kraft paper. It is manufactured on a "corrugator laminator" or "corrugator" and is used to make corrugated boxes. Corrugated paper is made from a material called corrugated cardboard, which consists of a layer of corrugated cardboard sandwiched between two layers of flat cardboard. This structure gives corrugated paper its unique strength and durability, making it an ideal packaging material.

Corrugated board weight

The thickness of corrugated board is expressed by the number of corrugated corrugated boards per meter, such as A corrugated board, B corrugated board, C corrugated board, etc. Corrugated cardboard boxes can hold 60 to 150 pounds, making them an excellent investment for holding heavier items. The size can be customized according to needs, from small boxes to large boxes, all can be made using corrugated paper.

Types of corrugated cardboard

Single-sided cardboard: Single-sided cardboard has only two layers, the lining layer and the corrugated layer. It is not as durable as other types of corrugated cardboard, but is often used inside boxes to add extra cushioning.

Single Wall Panel: Single wall panel is the most common type of corrugated fiberboard. If someone talks about corrugated cardboard, they are most likely referring to this style. It consists of two outer liners and a middle layer of corrugated media.

Triple-layer wallboard: Triple-layer cardboard is strong enough to be used in place of wooden boxes. Triple-ply corrugated cardboard makes this corrugated board a reliable choice for shipping chemicals or items that require special handling.

What is the difference between cardboard and corrugated cardboard?

Regular cardboard is generally thicker and heavier, while corrugated cardboard is more durable and has a different internal structure that is less dense and stronger,such as

Disposable Cardboard Box For Pizza. Corrugated cardboard is made from three layers to provide extra strength and withstand wear and tear.

Corrugated paper production process

The production process of corrugated paper is relatively simple and mainly includes the steps of raw material preparation, corrugated board production, cutting and forming. First, raw materials include pulp and glue, which are mixed together and passed through a series of processing equipment to form corrugated board. The cardboard is then cut and shaped as needed, ultimately forming a variety of corrugated products.

Application of corrugated paper in disposable packaging products

Corrugated paper can be easily made into packaging boxes of various shapes and sizes. Corrugated paper is an affordable packaging raw material that is recyclable, biodegradable, environmentally friendly, lightweight, strong and cost-effective. At Hydepackage, corrugated paper is often used to produce

disposable paper supplies or food packaging boxes, such as

corrugated paper cup holder,

Disposable PE Coated Paper Cup , custom pizza boxes, corrugated cups, food packaging boxes, paper bags, etc. Our team is dedicated to providing you with customized, protective and ecp-friendly packaging to meet your brand values and customer expectations. While used in the factory, it also provides good packaging impact.

489

489 0

0

Health Concerns With Disposable Paper Plate Usage

Health Concerns With Disposable Paper Plate Usage

Understanding PE Coated Paper

Understanding PE Coated Paper

Versatile Bamboo Sticks: Types, Uses, and Benefits

Versatile Bamboo Sticks: Types, Uses, and Benefits

Styrofoam Cups and Paper Cups

Styrofoam Cups and Paper Cups